100% Original Filter Bag - 4New LM Series Magnetic Separator – 4New

100% Original Filter Bag - 4New LM Series Magnetic Separator – 4New Detail:

Roller type magnetic separator

The press roll type magnetic separation device is mainly composed of a tank, a strong magnetic roller, rubber rollers, a reducer motor, a stainless steel scraper and transmission parts. The dirty cutting fluid flows into the magnetic separation device. Through the adsorption of the powerful magnetic drum in the separator, most of the magnetic conductive iron filings, impurities, wear debris, etc. in the dirty fluid are separated and tightly adsorbed on the surface of the magnetic drum. The pre-separated cutting fluid flows out of the bottom water outlet and falls into the lower liquid storage tank. The magnetic drum keeps rotating under the drive of the reduction motor, while the rubber roller installed on the magnetic drum continuously squeezes the residual liquid in the debris impurities, and the squeezed debris impurities are scraped off by the stainless steel scraper tightly pressed on the magnetic drum and fall down the sludge bin.

Disk type magnetic separator

Disk type magnetic separation device is composed of chassis, disk, strong magnetic ring, reduction motor, stainless steel scraper and transmission parts. The dirty cutting fluid flows into the magnetic separation device, and most of the magnetic conductive iron filings and impurities in the dirty fluid are separated by the adsorption of the strong magnetic ring in the magnetic cylinder. The iron scraps and impurities adsorbed on the disk and magnetic ring are scraped off by the stainless steel scraper tightly pressed on the magnetic ring and falls down to the sludge bin, while the cutting fluid after pre-separation flows out of the bottom liquid outlet and falls into the liquid storage tank below.

The magnetic separation device is designed to add disc components, which is conducive to improving the adsorption capacity of impurities, protecting the magnetic ring from external force impact, and effectively extending the service life of the magnetic ring.

Double layer disk type magnetic separator

The magnetic separator consists of case, magnetic drum, gear-motor, stainless steel scraper and transmission parts. When dirty oil enter the magnetic separator, most ferrous sludge in the dirty oil are attracted on the surface of magnetic drum, and the liquid is extruded by the roller, the dry sludge is scraped by stainless steel scraper and fall down to the sludge bin.

The capacity of one unit is 50LPM~1000LPM, and have multi way to let the coolant enter. 4New can also supply more big flow rate or much higher separator efficiency.

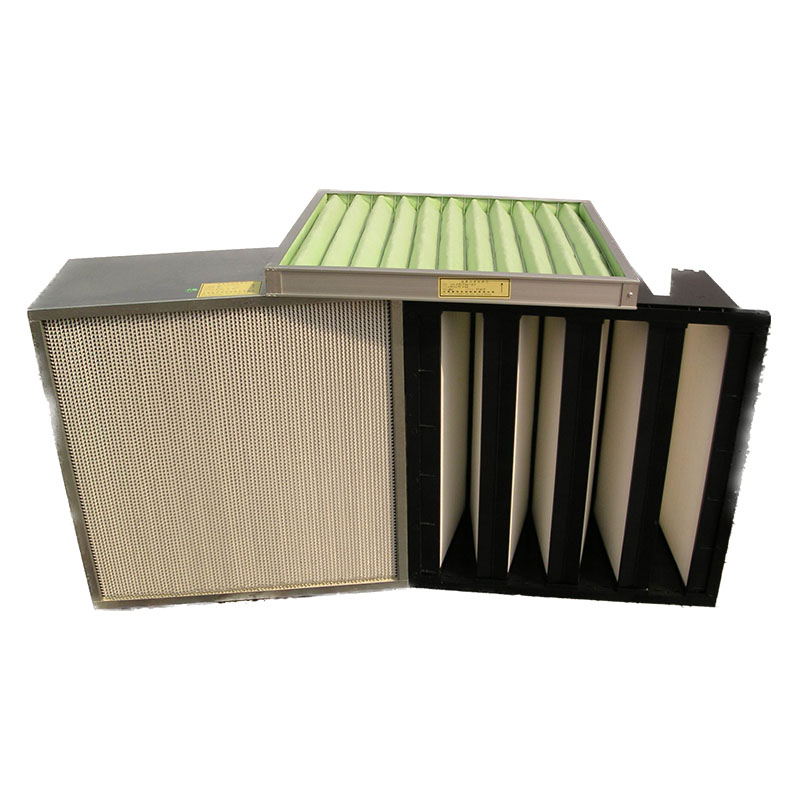

Product detail pictures:

Related Product Guide:

We can always satisfy our respected customers with our good quality, good price and good service due to we are more professional and more hard-working and do it in cost-effective way for 100% Original Filter Bag - 4New LM Series Magnetic Separator – 4New , The product will supply to all over the world, such as: Bogota, Amsterdam, Yemen, Our items have national accreditation requirements for qualified, high quality goods, affordable value, was welcomed by people today all over the world. Our products will continue to enhance within the order and look forward to cooperation with you, Should really any of these products and solutions be of curiosity to you, be sure to letus know. We are likely to be content to offer you a quotation up on receipt of your detailed needs.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.